About Us

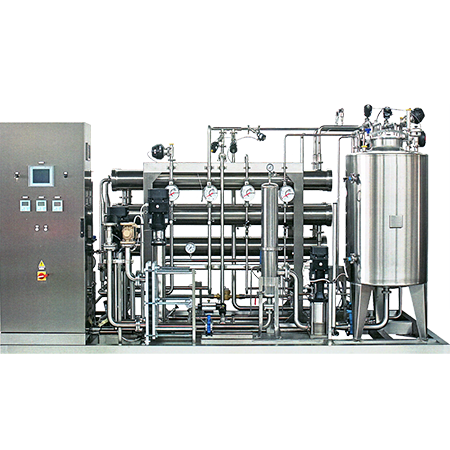

Prowaytek, established in 2009, is an experienced and fast moving company which is focused on PW & WFI systems in the medical, pharmaceutical and research facilities.

Our Advantage

Product Display

News Center

Online Message

Copyright © 2018-2020 PROWAYTEK SHANDONG MEDICAL DEVICE TECHNOLOGY CO.,LTD All Rights Reserved.

- To top